About Global Lift Used Forklifts Rhode Island

Global Lift Rhode Island - A forklift purchase is not to be taken lightly. A forklift is a large capital expenditure, and a complex machine with a motor strong enough to perform heavy-lifting jobs. The price tag for a forklift ranges from $10,000 to $30,000, comparable to the cost of a small truck. If purchasing a second-hand forklift, be certain to have it checked for potential mechanical issues.

There are two various types of forklift motor: internal combustion or electric. Forklifts with electric motors are usually more expensive than those with internal combustion motors. The motor size must suit the kind of work for which the forklift will be used. A forklift with a motor which is big costs much more compared to one with a smaller motor.

Gasoline or propane powered motors are usually stronger than electric motor and are capable of raising heavier weight. The downside is that gas motors tend to develop problems more often than electric motors. Depending on the price of gas or propane, gas powered forklifts can be more expensive to run than electric powered forklifts.

Reliable forklift manufacturers include Mitsubishi Caterpillar, Crown Equipment Corp., Toyota Industries and NACCO Industries. Before deciding, research the various manufacturers and the availability of parts. Reviews, testimonials and prices can be found on the Internet.

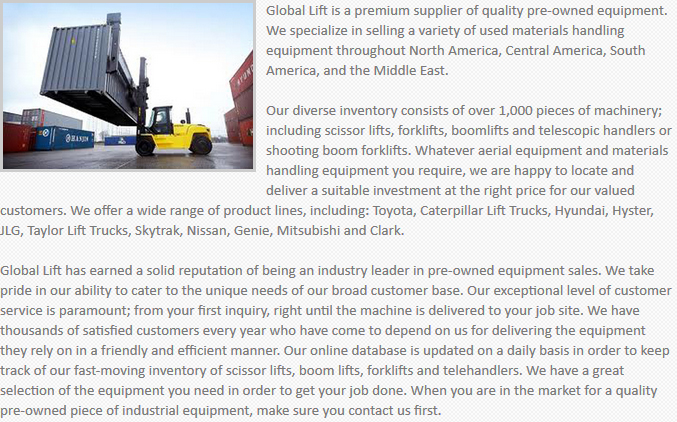

A forklift are a kind of equipment that allows an operator to easily and efficiently carry and move objects that are heavy or bulky. Forklifts are also known as industrial-powered trucks. They are an essential tool used for moving merchandise and cargo through the logistical supply chain. Forklifts are either diesel- or gas-powered or electrically-powered. Gas-powered models run on liquid propane gas, gasoline or diesel. Training in forklift operation and safety, like correct fueling procedures, is vital for all operators of forklifts.

There are a wide array of forklifts, each designed for different applications and environments. Forklift types include narrow aisle, side loader, sit-down units and reach trucks. Your choice of a forklift would depend on the specific tasks which would be carried out.

Within the United States alone around one hundred individuals are killed in forklift-related accidents every year. Many more people receive serious injuries in forklift mishaps. Proper safety training is required so as to lessen the risk of accident.

Either gasoline, diesel, battery or propane are utilized to power forklifts. Each different type is suitable to a different workplace environment.

Forklifts come with metal forks that are used to lift heavy materials. Possible attachments consist of buckets, clamps and hoists.

Forklifts must maneuver within warehouse environments that have very narrow aisles and a tight turning radius. There are certain kinds of forklift designed for this particular type of environment. Narrow aisle forklifts enable a distribution center or warehouse to provide a lot more space to goods.

Forklifts are powered lift trucks that are used in various kinds of industries to move heavy supplies and items. Forklifts are tough and dependable machinery that are necessary tools in warehouse and construction settings. Forklift models vary depending on the kind of fuel which is used to power the lift truck and the kind of work setting.

Electric powered lift trucks are great for indoor settings, or in sites with limited ventilation as they make no exhaust fumes. They are designed with industrial strength batteries. Because the electric forklift batteries should be charging, the worksite would need a charging station. The batteries are durable and can be re-charged up to 1,500 times before they have to be replaced. The charging station must be located in a ventilated area and include an acid spill kit and an emergency eyewash station.

Liquid propane powered forklifts are commonly utilized in modern industrial operations since propane has some benefits over diesel and electric. Propane models are cleaner to utilize than diesel-powered units. There is no down time required to recharge an industrial battery, and the cost for propane is less compared to the cost of electricity. A forklift propane tank can be refueled easily and quickly by changing out the empty tank with a full tank. Typically an off-site supplier refills the empty tank, making refueling very safe and efficient.

For outdoor applications and rough terrain, the diesel and gas forklifts are the machines of choice. These machinery are quite common on construction sites and in lumber yards. Their disadvantages include relatively high fuel costs, fairly high maintenance requirements and odorous exhaust. Their benefits include a longer lifespan compared to other units and dependability in tough conditions. Diesel and gasoline units must be refueled at a supply station on site that meets safety and health policies.

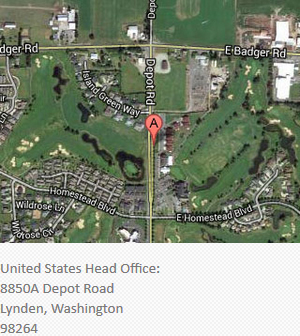

Contact Info

Fax: 1-888-029-0202

Fax: 1-888-029-0202

Questions or Comments